Contact Sales Fox Thermal

Fill out the form below to contact a Fox Thermal Representative.

Need to talk to someone immediately, give us a call, 831-384-4300.

Account Logout

Are you sure you want to log out?

Inline thermal mass flow meters from Fox Thermal provide highly accurate flow measurement for air, natural gas, and other process gas flow control. Inline flow meters may be equipped with NPT ends (pictured right) or flanged end connections.

Compare Products

Fox Thermal’s inline flow meter sensing elements are pre-aligned with the flow body’s centerline. The factory-configured depth setting of the probe/sensor ensures the most accurate measurement of gas in the pipe.

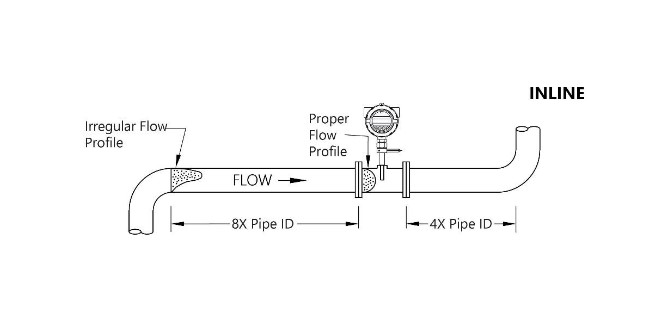

Compared with insertion-style flow meters, inline gas flow meters require shorter straight runs. This is in part due to the built-in flow conditioner which corrects distortion and swirl disturbances to the flow profile of the process gas, resulting in a uniform flow profile necessary for accurate flow measurement.

Fox Thermal offers remote inline-style flow meters for cases where the flow body installation location would make viewing the flow meter’s display difficult. These have a separate electronics enclosure that can be connected by cable to a remote junction box fitted to the probe and flow body assembly.

Many factors influence the style of flow meter to choose for a particular application. There may be pressure considerations, the possibility for corrosion, or physical limitations to the available process pipes.

Local inline-style flow meters have an electronics enclosure connected to a probe that is pre-installed in a section of pipe called a flow body. The flow body may be equipped with different process connections like NPT ends or flanges. NPT ends are commonly used in applications with smaller pipe sizes (up to 3-inch). Flanged end connections are routinely used for larger pipe sizes and in applications where threaded connections are not viable.

The flow body size should match the pipe size to which it is being connected. This ensures that there is not a pressure drop that may affect process function or the accuracy of the flow meter.

For the most accurate flow measurement, a uniform flow profile is preferred. This can be achieved either through the addition of straight pipe runs between the causes of turbulent flow or through the addition of a flow conditioning device.

Lateral placement of the flow meter on the process pipe is determined by the upstream and downstream straight run requirements of the style of flow meter and the existence of obstructions or elbows in the pipe that create swirl or turbulent flow profiles.

At Fox Thermal, our inline mass flow meters are constructed with built-in flow conditioners and straight run requirements are less than the requirements for insertion-style flow meters. We recommend that our inline flow meters be positioned with at least 8 diameters of straight, unobstructed pipe lengths upstream and 4 downstream.

Get a Quote

If you’re not sure which meter is right for your application, our Help Me Choose app walks you through a short series of questions to help you choose the ideal meter.

Next, enter your process data and flow meter requirements into our automated product configurator. Drop-down menus and Help icons will guide you to answer each question.

Save the data you entered into the configurator to create a PDF with a model code and AppID. When you're ready, submit your application to Fox Thermal for a quote.

The Model FT1 thermal flow meter available with Gas-SelectX® is easily reprogrammed in the field with the help of DDC-Sensor™ for calculating accurate gas correlations. It can measure a single gas or a mixture of up to 5 specified gases. The CAL-V™ Calibration Validation test feature ensures the meter retains its original NIST calibration.

Model FT1 is available in the inline style for pipes of ¾"-6" in diameter.

Available in an extended temperature operating range, the Model FT2A can be calibrated to measure an extensive list of dry pure gases and gas mixes.

This model is available in an inline style with built-in flow conditioners for pipes from ½" - 6" in diameter. The remote sensor mounting is optional.

The FT3 can operate over higher temperatures and measure a wide range of dry pure gases and gas mixes. Comes with CAL-V™ and Zero CAL-CHECK®. An optional Data Logger is available.

The Fox Thermal Model FT3 is available in an inline style for ½" - 6" pipes. A remote sensor mounting is optional.

This versatile gas flow meter is available with CAL-V™ Calibration Validation, DDC-Sensor™, and Gas-SelectX® allowing it to be programmed to measure any combination of gases in the gas mix menu in 0.1% increments to create a custom gas mix.

Model FT4 is available as an inline flow meter for pipe sizes from ¾"-6".

The Model FT4X features CAL-V™ Calibration Validation, DDC-Sensor™, and Gas-SelectX®. It comes with a built-in data logger for advanced record-keeping and data retention.

The Model FT4X is available with inline flow bodies with NPT ends (3/4" - 3" pipes), and Inline 150# & 300# flanged flow bodies (3/4" - 6" pipes). The remote sensor mounting is optional.

Find out more about the features and benefits of our range of advanced thermal flow meters and how they can help your flare gas flow measurement application.

Find the best type of gas flow meter for your application.

Here’s where you can find our product literature and brochures, articles and editorials, software downloads, FAQ, and more.